Battle-Ready Swords: What Makes a Truly Functional Blade? (A Buyer’s Guide)

2025-03-16

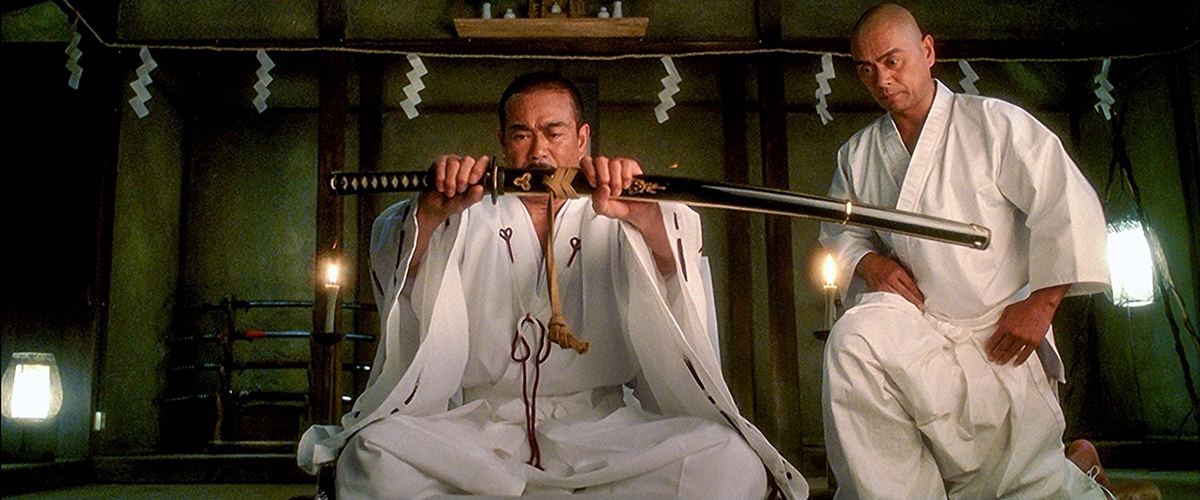

Swords have long captivated history buffs, martial artists, and collectors alike. But if you’re seeking a blade designed for real-world use—whether for cutting practice, historical reenactments, or martial arts like Bushido, Iaido, HEMA (Historical European Martial Arts)—not every sword will do. The term "battle-ready" isn’t just marketing jargon; it signifies rigorous craftsmanship, durable materials, and safety-tested engineering.

Here’s what separates a true battle-ready sword from decorative wall hangers—and how to choose a functional blade that won’t fail when it matters most.

1. The Anatomy of a Battle-Ready Sword

A functional sword isn’t merely sharp; it’s built to withstand impact, retain its edge, and balance power with precision. Key features include:

- Good Steel: Look for blades forged from 1060, 1095, T10 steel, 65Mn, S7, 3V, Manganese steel, Tamahagane steel. These alloys offer the perfect balance of hardness (for edge retention) and flexibility (to resist snapping under stress). Avoid stainless steel or “display-grade” metals—they’re brittle and prone to breakage.

- Full Tang Construction: The blade’s metal must extend fully through the handle (tang). Partial or “rat-tail” tangs are weak points prone to snapping, making them dangerous for sparring.

- Distal Taper & Balance: A well-designed blade thickens near the hilt and tapers toward the tip, ensuring agility without sacrificing strength. A pommel (end cap) acts as a counterweight for better control.

2. How Battle-Ready Swords Are Made

Authentic functional swords rely on time-tested methods:

- Hand-Forged vs Cast Metal: Battle-ready blades are shaped by skilled blacksmiths through hammer-forging—a process that aligns the steel’s grain for durability. Decorative swords are often cast in molds, creating weak, porous structures.

- Peened vs Screwed Hilts: Functional swords secure their handles via peening (hammering the tang’s end into a rivet-like cap) or epoxy. Screw-on pommels, common in decorative swords, can loosen during use.

- Stress Testing: Reputable makers test blades by striking hard objects, bending them, and slicing through targets like mats or bamboo.

3. Functional vs Decorative: Red Flags to Avoid

Before buying, watch for these warning signs of a "wall-hanger":

- ⚠️ Stainless Steel Blades: Too brittle for impact.

- ⚠️ Partial Tangs: Loose or wobbly handles signal weak construction.

- ⚠️ Poor Balance: A top-heavy or flimsy feel indicates flawed design.

- ⚠️ Unsharpened Edges: A true battle-ready blade will have a honed, durable edge.

4. How to Use a Battle-Ready Sword Safely

Even functional blades demand respect:

- Training First: Always practice under a qualified instructor.

- Safety Gear: Wear gloves, eye protection, and padded gear for sparring.

- Maintenance: Clean and oil carbon steel blades regularly to prevent rust.

5. Legal Considerations

Check local laws before purchasing. Some regions restrict blade length or require permits for owning sharps.

Final Tip: Trust Reputable Makers

Brands like Spartan Blades Club(CHEN'S SWORDS 1892) combine historical techniques with modern metallurgy. Read reviews, ask about warranties, and confirm testing standards.

Ready to wield history? Whether you’re a martial artist, collector, or reenactor, a battle-ready sword offers unmatched authenticity. Just remember: Functionality is forged, not faked.

FAQ Section:

- Q: Can battle-ready swords be used for cutting practice?

- A: Yes! Many are tested on mats or bamboo—but always use proper targets.

- Q: What’s the price range for a quality battle-ready sword?

- A: Expect $200 - $1000+ depending on materials and craftsmanship.

- Q: Are battle-ready katanas different from European swords?

- A: Yes—designs vary, but the principles (full tang, carbon steel) remain universal.

USD

USD